7 things to note when customizing cutting tools

When designing and using customized cutting tools, several important factors must be considered to ensure the performance of the tool and production efficiency. Below are seven key considerations:

-

Material Selection

Choosing the appropriate tool material based on the properties of the workpiece material is crucial. The selection of tool material will affect the tool's wear resistance, heat resistance, and overall lifespan. For example, tungsten carbide is typically suitable for highhardness materials, while highspeed steel is ideal for general purposes.

-

Cutting Parameter Design

Cutting parameters such as cutting speed, feed rate, and depth of cut need to be adjusted according to the workpiece material and machine capability. These parameters not only impact machining efficiency but also affect the quality of the machining and the tool's lifespan.

-

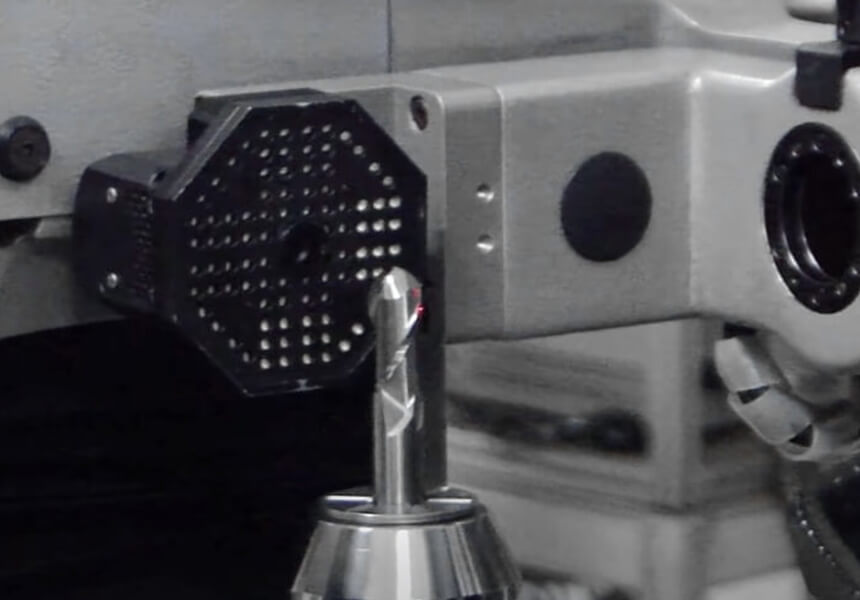

Tool Geometry

The geometry of the tool, such as rake angle, clearance angle, and edge shape, influences cutting force and chip evacuation. Proper geometric design can reduce cutting force, minimize tool wear, and improve the surface quality of the workpiece.

-

Tool Coating

Coatings can enhance the wear resistance and oxidation resistance of the tool. Choosing the right coating (such as TiN, TiAlN, ZrN, etc.) can extend the tool's lifespan and improve machining performance.

-

Tool Cooling Method

When cutting at high temperatures or machining difficulttocut materials, using appropriate coolants and cooling methods (such as internal cooling, external cooling, or mist cooling) can effectively reduce cutting temperature and mitigate the impact of heat on the tool and workpiece.

-

Tool Manufacturing Precision

The manufacturing precision of the tool directly affects machining accuracy and the surface quality of the workpiece. Highprecision tools can reduce dimensional deviations and surface roughness of the workpiece, meeting the requirements of highprecision machining.

-

Tool Maintenance and Care

Regular inspection and maintenance of tools can extend their lifespan and ensure stable performance. This includes regularly replacing tools, checking for wear conditions, and ensuring the tools are clean.

The design and use of customized cutting tools involve multiple critical factors, each significantly impacting machining efficiency and product quality. Considering the seven key factors mentioned above can help in selecting and designing the most suitable tool solutions to meet the demands of various machining conditions and materials.